We don’t realize the work of a jacket’s creation. That’s why, Alizée is listing you the steps from designing the jacket to buying it from your favorite retailer.

At Alizée, the development of a collection is done by several people, as a team. In the Quebec City’s offices, the designer-patronist and production team works together with the sales team to create quality, comfortable and stylish clothing, designed for Canadian winters. The production cycle of a jacket is planned over 2 years and is more complex since the collection is not entirely made here. However, Alizée wants to make sure that its products are assembled in factories that meet the highest environmental and ethical standards. This is why each partner manufacture is Bluesign certified.

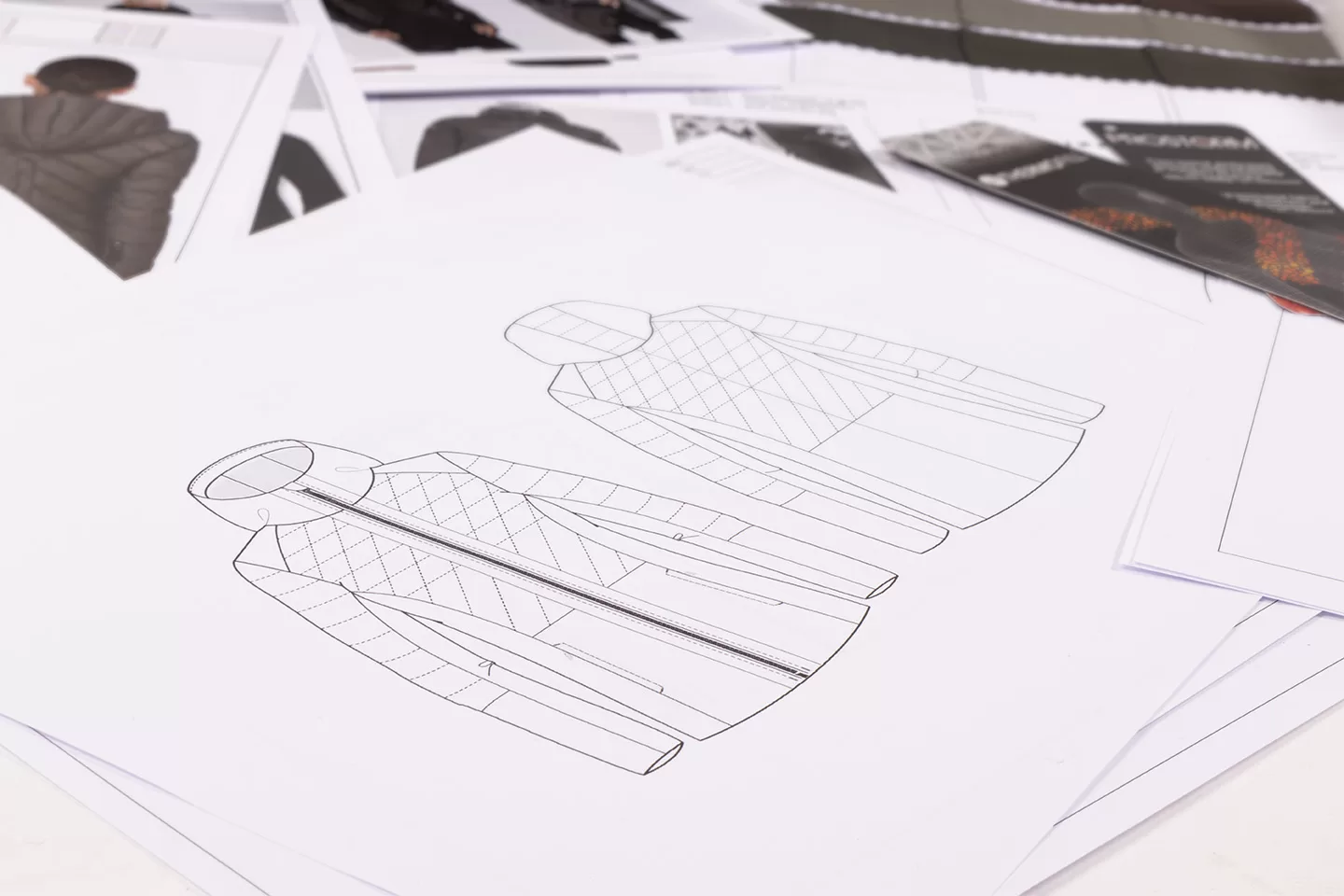

1 – The design’s process

As said above, the development of a collection takes place over a period of 18 to 24 months. First of all, you have to think about the design. It is necessary to think about all the elements that must be found in a jacket: pockets, drawcords, fixed or removable hood, etc. You also have to consider the length of the jacket, the weight of the insulation, the technical features of the material and its performance. Finally, you have to choose a style and its colors palette.

At Alizée, this step, lasts about 4 months and takes place from December to March, the following year.

2 – The prototype’s making

Once the design is completed, you can start making a first confection. This first sample, commonly called a prototype, is the start of this next process. Made with available materials (not the right fabric, not the right color, not the right insulation, not the right accessories, etc.), it allows you to see the construction of the jacket and make the required adjustments. Once the model looks final, the SMS (Sales Merchant Samples) are made. They will be used by the sales representatives in order to present the finished products to the retailers. These merchants will decide which jackets they will present to their consumers.

This process takes place from March to November.

3 – The presentation to retailers

Although the elaborate collection features around thirty styles in 4 or 5 colors each, the final production often only represents a more or less negligible portion of the clothes presented. Some styles never make it to consumers. The merchants, who choose jackets in greater number, choose the styles they deem best suited for their customers.

This step takes place from November to February, the following year.

4 – The fabrics and accessories’ production

Once the presentation’s step is done, it is time for the retailers’ orders and the start of production. It is required to begin the work of weaving the fabric at the same time as the sales meetings. Therefore, you have to anticipate based on the first meetings with retailers. Plan the quantities of fabrics necessary to make the jackets and styles that have been chosen and that needs to be delivered the following year. Fabrics take around 6 to 8 weeks to be made and dyed. At the same time, the other accessories necessary for the final manufacture of the jacket will be producted (zippers, filling, cords, buttons, labels, packaging, etc.)

This phase takes place from December to February.

5 – The jacket’s assembling

All these components are then sent to the factory in charge of assembling all the parts that will create the final product. However, you have to consider the production’s country holidays. For example, factories are closed during Chinese New Year, which lasts for 4-6 weeks. Therefore, you have to ensure that this period of leave is aligned with the manufacturing stages, so it doesn’t create any additional delay in the production process.

For Alizée’s jackets, it takes places from January to July.

6 – The jacket’s transportation

Finally, there is the step of transportation. This last step is the most uncertain of all. There is a need to coordinate the road transport from the factory to the port in China. Synchronize everything with the maritime transport of goods, customs and rail or road transport once in Canada. If the jackets arrive in the country through the Port of Prince Ruppert in Vancouver, the shipment will take the train across the country and end its route by truck. If it is processed at the Port of Montreal, the times will differ. The load’s inspection is carried out by the Canada Customs service and, once released, it resumes its journey to the warehouses where the shipping service assembles the orders, by store, and ships everything to the retailers.

This step can take 3 weeks, at the quickest. But strikes, storms, equipment breakdown, customs delays, transport delays are numerous elements, beyond Alizée’s teams control, that can cause the arrival dates in store to vary.

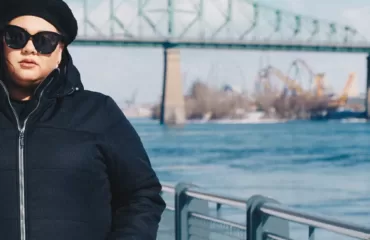

7 – The sale and promotion to the consumer

Once in store, the jacket are presented to consumers. But the company still works on this collection to promote it. It is being planned and prepared several months in advance. Photoshoots or videos are made during the summer, fall and winter a year before to put in magazines, on the web or in posters at retailers. Catalogs are prepared for buyers and distributed the previous year too. The social media and web marketing strategy is in preparation the fall of the year before and runs throughout the whole year.

Alizée’s team has worked hard for 2 years to offer a collection of quality, affordable, comfortable, eco-friendly and above all stylish. The whole team is working to keep the wheel spinning without a hitch. They all hope that their efforts will provide you warmth and comfort in the coldest winters and that you will proudly wear your Alizée jacket.

|